The Duty of a Membrane Switch in Modern Touch Interfaces and Controls

The Duty of a Membrane Switch in Modern Touch Interfaces and Controls

Blog Article

Comprehending the Capability of Membrane Changes for User Interface Devices

The performance of membrane layer switches over stands for a significant improvement in individual interface layout, integrating performance with visual adaptability. As markets increasingly focus on individual experience, understanding the subtleties of membrane layer button modern technology becomes essential.

What Are Membrane Buttons?

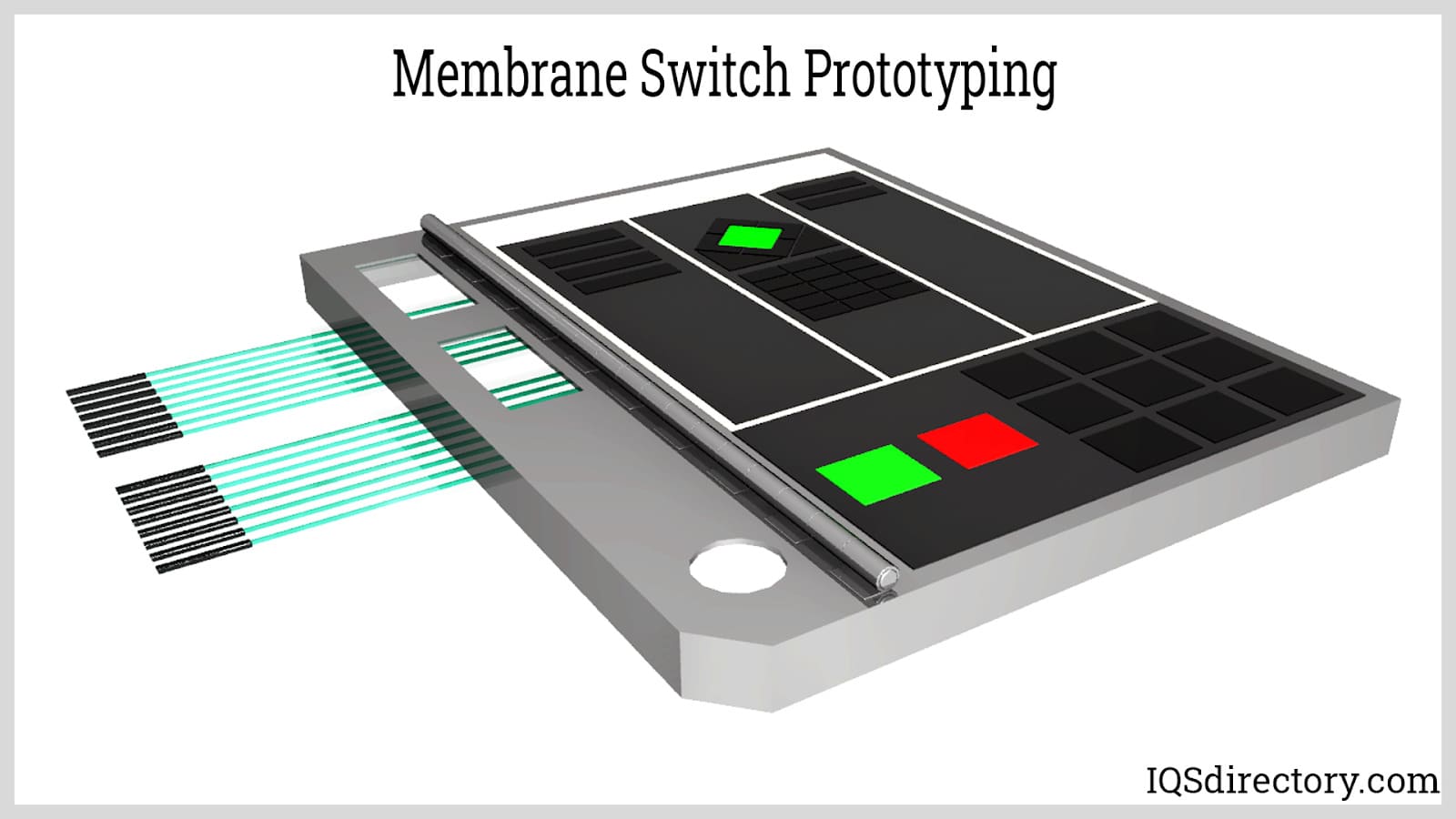

Membrane layer buttons are cutting-edge user interface devices that promote customer interaction with electronic equipment. These flexible parts are composed of numerous layers, including a visuals overlay, spacer, and a published circuit layer. The style permits a seamless assimilation right into different electronic gadgets, improving both the aesthetic and functional facets of customer interfaces.

Membrane buttons are typically employed in a large range of applications, from home devices to industrial equipment and clinical devices. Their building usually features a slim profile, making them a perfect selection for portable designs. The tactile feedback given by these buttons can be crafted to meet certain customer preferences, making certain efficient communication between the individual and the tool.

Resilience is one more considerable benefit of membrane switches, as they are resistant to dust, wetness, and chemicals, which enhances their lifespan popular settings. Furthermore, these buttons can be customized in regards to shape, dimension, and visuals layout, enabling branding and user-specific functions. On the whole, membrane switches represent a useful remedy for enhancing user experience in digital devices, combining functionality with aesthetic charm in a reliable fashion.

Exactly How Membrane Switches Over Work

Operating on an uncomplicated principle, membrane layer switches use a split building to register customer input successfully. Each button contains numerous layers, consisting of a printed circuit layer, a spacer layer, and a top graphic layer, which are developed to interact flawlessly. When a user presses the leading layer, it presses the spacer layer, bringing the conductive aspects of the circuit layer into contact with each other.

This contact produces a shut circuit, indicating the tool to carry out a certain feature. The design permits for different arrangements, consisting of responsive responses, which can improve the individual experience by supplying a physical feeling upon activation. The products made use of in membrane layer switches often consist of flexible substrates, such as polyester or polycarbonate, which ensure longevity and resilience versus deterioration.

Key Benefits of Membrane Buttons

One more considerable advantage is their compactness. Membrane layer switches are thin and lightweight, which enables makers to save room in their tools without sacrificing functionality. This feature is especially beneficial in applications where weight and quantity are essential factors to consider.

Furthermore, membrane buttons are immune to dust, moisture, and chemicals, improving their durability. This strength expands their life-span and minimizes the demand for constant substitutes, causing cost savings with time.

In addition, the responsive comments offered by membrane layer switches can be optimized to improve user interaction. They can consist of features such as elevated buttons or distinct clicks, boosting usability and customer experience.

Applications Throughout Industries

Customer user interface devices using membrane layer buttons prevail in a wide selection of markets, showcasing their flexibility and functionality. Membrane Switch. In the medical industry, membrane switches are important to tools such as diagnostic devices and patient monitoring systems, where their toughness and simplicity of cleansing are important for maintaining health standards. In a similar way, in the vehicle industry, these buttons are used in control panel controls and infotainment systems, supplying a sleek and modern-day interface for users.

In addition, the customer electronic devices sector take advantage of membrane layer buttons in home appliances and handheld gadgets, where compact style and straightforward user interfaces enhance customer experience. Industrial applications likewise utilize membrane switches for control panels in machinery and automation systems, highlighting their effectiveness and resistance visit homepage to extreme environments.

In the aerospace and defense industries, membrane layer buttons are used in cabin controls and directory devices, where reliability and efficiency under severe problems are vital. In addition, the gaming sector increasingly incorporates membrane switches in controllers and gallery devices, adding to an appealing individual experience. Overall, the flexibility of membrane layer changes enables their widespread usage throughout numerous industries, underscoring their importance in contemporary interface style.

Future Patterns in Membrane Layer Change Innovation

Furthermore, making use of sophisticated materials, such as polycarbonate and polyester movies, is anticipated to increase, providing boosted resilience and resistance to ecological stress factors. These products contribute to the total long life of membrane buttons, making them appropriate for harsher industrial applications.

Moreover, the consolidation of smart modern technology, consisting of IoT connection, will certainly enable membrane buttons to connect with various other gadgets and systems, facilitating an extra interactive individual experience. This fad aligns with the expanding need for clever devices across different fields, from health care to consumer electronic devices.

Lastly, customization options are anticipated to increase, allowing suppliers to develop bespoke services customized to particular individual needs and choices. These advancements will certainly place membrane switches as vital components in the development of interface modern technology.

Final Thought

In final thought, membrane layer switches stand for a critical innovation in user interface innovation, using a reputable and flexible service for varied digital applications. As improvements in product science and touch sensing modern technologies continue, the performance and applicability of membrane layer switches are anticipated to increase, strengthening their significance in modern digital devices.

Report this page